Imagine a bustling oil refinery, where vast quantities of liquid kerosene are constantly in motion. It’s essential to know precisely how much kerosene is flowing through pipelines and processing units. This is where the venturi meter comes into play, a vital instrument for measuring the flow rate of liquids like kerosene, gasoline, and even crude oil. The venturi meter’s simple yet effective design allows us to monitor and control these crucial fluids, ensuring efficient operation and safety within the industry.

Image: www.coursehero.com

Venturi meters are a cornerstone of fluid dynamics, showcasing the fascinating relationship between fluid velocity and pressure. Their widespread use in various sectors, including oil and gas, water treatment, and even aerospace, highlights their importance in understanding and controlling fluid flow.

Delving Into the World of Venturi Meters

Venturi meters are cleverly designed devices that measure the flow rate of a fluid by exploiting the principle of Bernoulli’s equation. This equation states that as the velocity of a fluid increases, its pressure decreases. In a venturi meter, the fluid is forced through a constricted section called a throat, causing its velocity to increase and pressure to drop. The difference in pressure between the wider section (upstream) and the constricted section (throat) is directly proportional to the fluid’s flow rate.

Venturi Meter Anatomy: A Closer Look

A typical venturi meter consists of several key components:

- Upstream Section: This wider section is where the fluid enters the meter. The pressure here is relatively high.

- Throat: The constricted section where the fluid velocity increases and pressure drops. The pressure here is lower than in the upstream section.

- Downstream Section: After the throat, the fluid expands back to its original diameter. The pressure starts to recover, but it’s still lower than the upstream pressure.

- Pressure Taps: These are small openings located in the upstream and throat sections, connected to pressure gauges or differential pressure transducers. These instruments measure the pressure difference between the two locations, which is used to calculate the flow rate.

Why Use Venturi Meters?

Venturi meters offer numerous advantages over other flow measurement methods, making them a popular choice in various applications:

- Accuracy: Venturi meters provide very accurate flow measurements, particularly for liquids with low viscosity, like kerosene.

- Low Pressure Loss: Compared to some other flow meters, venturi meters cause relatively low pressure loss, reducing energy consumption and improving efficiency.

- Reliability: Their simple design, with minimal moving parts, contributes to their durability and reliability over time.

- Wide Flow Range: Venturi meters can measure flow rates over a wide range, from very slow to very high flows.

Image: www.numerade.com

Liquid Kerosene and Venturi Meters: A Perfect Pair

Liquid kerosene, due to its low viscosity and relatively stable flow characteristics, is ideally suited for measurement using venturi meters. The venturi meter’s ability to accurately measure flow rates for a wide range of liquid kerosene flow rates makes it an invaluable tool for various processes.

Whether you’re monitoring kerosene flow in a refinery, managing fuel delivery systems, or measuring fuel consumption in an aircraft, venturi meters provide reliable and precise flow data. This information is crucial for optimizing operational efficiency, ensuring safety, and regulating fuel supply.

Venturi Meter Calibration and Accuracy

To ensure accurate flow measurement, venturi meters need to be carefully calibrated. This process involves comparing the meter’s readings to known standard flow rates. Calibration ensures that the meter’s output is consistent with actual flow rates.

Calibration is essential for maintaining the accuracy and reliability of the venturi meter over time. Regular calibration, especially in demanding environments like refineries, ensures that flow measurement data remains precise and dependable.

Trends and Developments in Venturi Meter Technology

The world of venturi meter technology is constantly evolving, driven by innovation and the search for greater efficiency. Recent advancements include:

- Smart Venturi Meters: Integration of sensors and communication technologies allows for real-time data monitoring, remote control, and predictive maintenance. This data can help optimize operations and reduce downtime.

- Advanced Materials: New materials, such as high-strength polymers and advanced ceramics, are making venturi meters more durable, resistant to corrosion, and capable of handling more demanding applications.

- Miniaturization: Smaller, more compact venturi meters are becoming available, making them ideal for space-constrained applications and for measuring flow rates in smaller pipelines.

Expert Tips for Using Venturi Meters

Based on my experience in the oil and gas industry, here are some expert tips for utilizing venturi meters effectively:

- Choose the Right Size: Selecting a venturi meter with the appropriate throat diameter is crucial for optimal performance. A meter that’s too small can lead to excessive pressure loss, while a meter that’s too large may not provide accurate readings at low flow rates.

- Proper Installation: Proper installation is essential. Ensure the venturi meter is straight and level, and that there are no obstructions or bends in the pipeline upstream of the meter.

- Regular Maintenance: Check for wear and tear, leaks, and ensure the pressure taps are clean and functioning properly. Regular maintenance helps to prevent errors and ensures long-term accuracy.

Venturi Meter FAQs

Here are some common questions about venturi meters:

Q: What is the difference between a venturi meter and an orifice plate?

A: Both venturi meters and orifice plates use the principle of differential pressure to measure flow rate. However, venturi meters have a gradual, conical contraction leading to the throat, while orifice plates have a sharp-edged hole. This difference in design results in a lower pressure loss for venturi meters compared to orifice plates.

Q: How do I calculate flow rate using a venturi meter?

A: The flow rate can be calculated using the Bernoulli equation and the measured pressure difference between the upstream section and the throat. The equation is: Q = K * (ΔP)^0.5, where Q is the flow rate, ΔP is the pressure difference, and K is a constant that depends on the venturi meter geometry and the fluid properties.

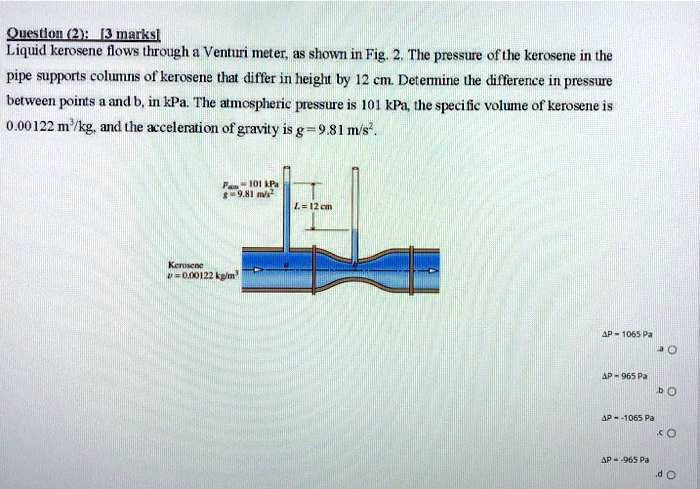

Liquid Kerosene Flows Through A Venturi Meter

Conclusion: Venturi Meters – A Flow Measurement Essential

Venturi meters are integral to many industries, playing a critical role in measuring the flow rate of liquids like kerosene with accuracy and reliability. Their simple yet effective design, coupled with ongoing technological advancements, ensures their continued relevance and importance in various industrial processes. Understanding the working principles of venturi meters can help you make informed decisions regarding flow measurement, control, and optimization.

Are you interested in learning more about venturi meters or their applications in your industry? Let me know in the comments below.