Imagine a vast reservoir, teeming with life but burdened with pollutants. How do we effectively separate the valuable water from the suspended solids, allowing for clean and safe use? This is where the humble rectangular sedimentation tank comes into play – a crucial component in water treatment plants, efficiently removing suspended particles from wastewater or raw water.

Image: www.mdpi.com

Designing and calculating the dimensions of a rectangular sedimentation tank is essential for optimal performance. This article will guide you through the fundamental principles of rectangular sedimentation tank design, exploring the essential calculations required for accurate sizing and efficiency.

Understanding the Basics

Sedimentation tanks are crucial for removing suspended solids from water through gravity settling. They operate on the principle of differences in density and particle size. The heavier particles settle to the bottom of the tank, forming a sludge layer, while the clarified water flows out from the top.

Key Design Parameters

Several key parameters influence the design of a rectangular sedimentation tank, including:

- Surface Overflow Rate (SOR): This crucial parameter determines the flow rate of water per unit surface area of the tank. It directly impacts settling efficiency and is typically expressed in meters per hour (m/h). Lower SOR values generally lead to better settling.

- Detention Time: The average time a particle spends within the sedimentation tank, crucial for complete settling and determined by dividing the tank volume by the flow rate.

- Hydraulic Loading Rate (HLR): Represents the volume of water treated per unit surface area per unit time. HLR is calculated by dividing the flow rate by the tank surface area.

- Length to Width Ratio (L:W): A key geometric parameter influencing flow distribution within the tank. Ideally, L:W ratios around 3:1 to 5:1 are preferred for more efficient settling.

Calculation Process

The design calculations involve a series of steps, ensuring a well-functioning sedimentation tank. Let’s break down the process:

Image: www.chegg.com

1. Determine the Flow Rate

Start by identifying the design flow rate of the wastewater stream. This value provides the basis for further calculations.

2. Decide the Desired SOR

Based on the water quality characteristics and desired settling efficiency, select a suitable surface overflow rate. Typical SOR values for sedimentation tanks range from 10 to 40 m/h, but the optimal value will depend on the specific application.

3. Calculate the Tank Surface Area

Divide the flow rate by the chosen surface overflow rate. This will provide the required surface area of the sedimentation tank.

4. Determine the Tank Volume

Multiply the tank surface area by the desired detention time. This determines the required volume of the tank, ensuring sufficient time for particle settling to occur.

5. Set the Length to Width Ratio

Choose a suitable length to width ratio for the tank, aiming for approximately 3:1 to 5:1 to facilitate uniform flow distribution and efficient settling. Consider the available space, construction constraints, and other practical factors.

6. Calculate the Tank Dimensions

Determine the tank’s length and width using the chosen length to width ratio and the calculated surface area. You can utilize the following equations:

- Length (L) = (L:W) * Width (W)

- Surface Area = L * W

7. Calculate the Depth

Divide the tank volume by the tank surface area to obtain the required depth of the sedimentation tank.

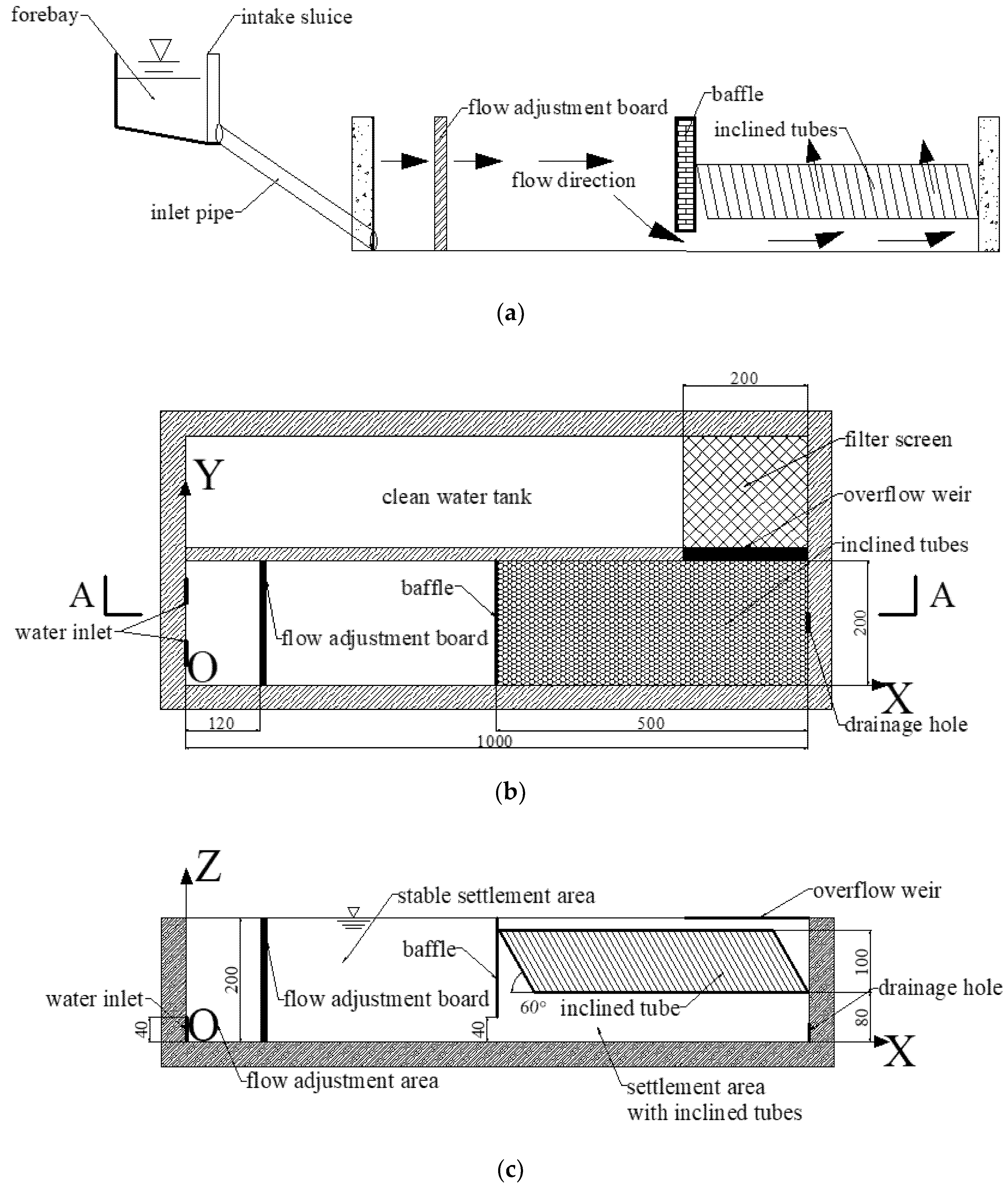

8. Design the Inlet and Outlet Structures

Proper inlet and outlet designs are crucial for efficient water flow and sedimentation. Inlet structures should distribute the incoming flow evenly across the tank’s width, preventing short-circuiting. Similarly, outlet structures should be designed to withdraw clarified water without disturbing the settled sludge layer.

9. Sludge Removal System

Design an effective sludge removal system, incorporating scrapers or other mechanisms to remove accumulated sludge from the bottom of the tank. Regular sludge removal is critical for maintaining optimal tank performance and preventing clogging.

Sample Calculations

Let’s consider an example to illustrate the application of these principles. Imagine a wastewater treatment plant treating a flow rate of 500 m³/h. Assume a SOR of 20 m/h is chosen for the sedimentation tank design.

We can calculate the required tank surface area as:

Surface Area = Flow Rate / SOR = 500 m³/h / 20 m/h = 25 m²

Assuming a length to width ratio of 4:1, we can determine the tank dimensions by applying the above equations:

Width = √(Surface Area / (L:W)) = √(25 m² / 4) ≈ 2.5 m

Length = (L:W) * Width = 4 * 2.5 m = 10 m

If we decide on a detention time of 2 hours, the required tank volume is:

Volume = Surface Area * Detention Time = 25 m² * 2 h = 50 m³

The depth of the tank can be calculated as:

Depth = Volume / Surface Area = 50 m³ / 25 m² = 2 m

Therefore, the required dimensions for this sedimentation tank would be 10 m (length) x 2.5 m (width) x 2 m (depth).

Factors Affecting Sedimentation Tank Design

Several additional factors can influence the design of a rectangular sedimentation tank:

- Water Quality: The concentration, size, and shape of particles in the water have a significant impact on sedimentation tank design. Higher concentrations of large, dense particles may require larger tanks, longer detention times, or specialized flocculation processes.

- Temperature: Water temperature can significantly affect settling efficiency. Lower temperatures can increase viscosity, hindering particle settling. Therefore, design considerations for colder climates may require adjustments to SOR or detention time.

- Sedimentation Tank Configuration: Variations in sedimentation tank configuration, such as the presence of baffles, may influence flow patterns and settling efficiency. Careful consideration of these factors can optimize tank performance for specific applications.

- Environmental Considerations: The choice of construction materials and the overall environmental impact of the sedimentation tank should be taken into account. Considering sustainability and minimizing footprint can be important aspects of a comprehensive design.

Rectangular Sedimentation Tank Design Calculations Pdf

Conclusion

Designing rectangular sedimentation tanks is a critical aspect of wastewater treatment. By understanding the key parameters, calculation process, and the influence of various factors, you can create efficient and effective systems for removing suspended solids from water. This guide provides a solid foundation for understanding the principles and calculations involved, empowering you to create solutions that ensure cleaner and safer water resources. Remember, thorough research and adherence to relevant regulations are essential for successful implementation.