The Cummins N14 is a legendary engine known for its power and reliability. Whether you’re a seasoned mechanic or a curious enthusiast, understanding the main bearing torque specs is crucial for proper maintenance and engine longevity. I remember the first time I encountered this spec while rebuilding a friend’s N14. It wasn’t the most straightforward thing to find, so I ended up scouring countless forums and online resources. This experience sparked my curiosity about the importance of these specs and how they ensure a smooth running engine.

Image: www.cumminsforum.com

This article will dive deep into the world of N14 Cummins main bearing torque specs, providing comprehensive information, practical tips, and expert advice. We’ll explore what these specs mean, why they matter, and how to find the right information for your specific engine. So, let’s get started and unravel the mysteries of these vital numbers.

Understanding N14 Cummins Main Bearing Torque Specs

The main bearing torque specs refer to the specific tightening force required for the bolts that hold the main bearing caps in place. These caps are essential for supporting the crankshaft, which is the rotating heart of the engine. The crankshaft rides on these bearings, and their proper installation is key to preventing premature wear and tear on the engine.

Tightening these bolts to the wrong torque can have disastrous consequences. Under-tightening can lead to crankshaft movement and excessive wear, while over-tightening can deform the engine block or even crack the main bearing caps. Having the right torque is crucial to creating a perfect fit and ensuring a long-lasting, reliable engine.

The Importance of Main Bearing Torque Specs

The main bearing torque specs are critical for ensuring the following:

- Proper bearing alignment: The main bearing caps need to be properly aligned and tightened to ensure the crankshaft rotates smoothly and evenly.

- Prevention of crankshaft movement: The torque specs ensure that the crankshaft stays in place and doesn’t move during operation, reducing wear and tear on the bearings.

- Engine longevity: Having the right torque helps minimize friction and heat buildup, maximizing the life of the engine’s components.

- Reduced vibration: Properly tightened main bearings contribute to a smoother engine operation, reducing excessive noise and vibration.

Where to Find N14 Cummins Main Bearing Torque Specs

Now let’s talk about where you can find these vital specs. The best approach is to use the official Cummins service manuals. These manuals provide precise specs for your specific N14 engine model and serial number. You can typically find these manuals online or through authorized Cummins dealers.

If you can’t easily access the service manual, you can also look to other reputable resources like:

- Cummins forums: These online communities often have experienced mechanics who can provide guidance and share their knowledge on specific torque specs.

- Online repair manuals: Websites like AllData and Mitchell 1 often have information on engine specifications.

- Repair shops: Local repair shops specializing in Cummins engines may be able to provide torque specs based on your engine model.

Remember, it’s important to use reliable and trustworthy resources to avoid misinterpretations or outdated information.

Image: dieselpro.com

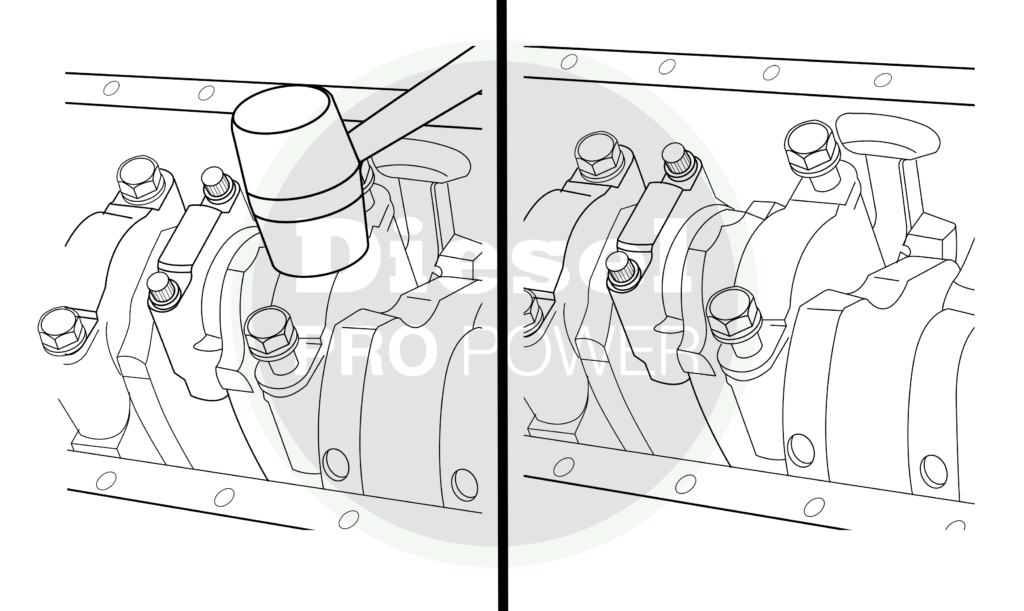

Tips and Expert Advice for N14 Cummins Main Bearing Torque

Here are some tips and expert advice for working with N14 Cummins main bearing torque specs:

- Always use a torque wrench: Never rely on “feel” when tightening bolts. A torque wrench ensures consistent and accurate tightening.

- Use the correct torque values: Double-check the specs for your specific engine and use them precisely. Avoid relying on general guidelines or previous experiences.

- Proper cleaning: Ensure the bolts and threads are clean before tightening to prevent seizing or uneven torque.

- Proper lubrication: Use appropriate lubricant on the bolts to prevent galling and ensure a smooth tightening process.

- Tighten in stages: Follow the recommended tightening sequence, typically in a “star pattern,” to ensure even tension and prevent stress on the block.

Always consult the N14 Cummins service manual for specific instructions and tightening sequences for your engine model. These steps will ensure you avoid over-tightening which could damage the engine, and that you have the proper torque and proper sequences for the job.

Frequently Asked Questions

What is the main bearing torque spec for a 1998 N14 Cummins?

The specific torque spec for a 1998 N14 Cummins will vary depending on the exact model and serial number of your engine. Refer to the official Cummins service manual for your specific engine to find the correct torque value.

Can I use a standard wrench to tighten the main bearing bolts?

No, you should never use a standard wrench for this task. Use a calibrated torque wrench to ensure accurate tightening and avoid damaging the engine.

Are there any other factors that influence main bearing torque?

Yes, factors like the condition of the engine block, the type of bolts used, and the ambient temperature can slightly influence the required torque. Consult the service manual for any specific adjustments based on your situation.

What happens if I over-tighten the main bearings?

Over-tightening can lead to several problems including:

- Deformation of the engine block

- Cracked main bearing caps

- Increased friction and wear on the bearings

- Premature engine failure

It is crucial to use the correct torque wrench and adhere to the prescribed specs to avoid over-tightening.

N14 Cummins Main Bearing Torque Specs

Conclusion

In conclusion, understanding the N14 Cummins main bearing torque specs is crucial for maintaining a reliable and long-lasting engine. By ensuring proper tightening with the correct tools and procedures, you can prevent costly repairs and optimize engine performance. Remember to always refer to the official Cummins service manual for your specific engine model.

Do you have any questions or need additional information about main bearing torque specs or the N14 Cummins engine? Let us know in the comments below. We’re here to help!